Harnessing the Power of AI: Revolutionizing Automated Warehouse Optimization

Revolutionizing Automated Warehouse Optimization

Harnessing the Power of AI: Revolutionizing Automated Warehouse Optimization

In the bustling world of logistics and supply chain management, efficiency is the name of the game. In recent years, the integration of Artificial Intelligence (AI) into automated warehouse systems has brought about a paradigm shift, unlocking unparalleled levels of optimization and productivity. As we delve deeper into the capabilities of AI, it becomes increasingly evident that its transformative influence extends far beyond mere automation; it is reshaping the very fabric of warehouse operations.

unlock

new

frontiers

At the heart of AI-driven warehouse optimization lies the ability to harness vast amounts of data in real-time. Through the deployment of sensors, RFID tags, and IoT devices, warehouses are now equipped with a treasure trove of information regarding inventory levels, product movement, and operational efficiency. AI algorithms sift through this data with lightning speed, identifying patterns, predicting demand fluctuations, and optimizing inventory placement to minimize storage costs and streamline fulfillment processes.

Adaptability and Scalability

One of the most significant advantages of AI in warehouse optimization is its adaptability and scalability. Traditional warehouse management systems often rely on predetermined rules and static algorithms, which may become obsolete in the face of dynamic market conditions or unforeseen disruptions. AI, on the other hand, possesses the capability to learn and evolve over time, continuously refining its models based on new data inputs and feedback loops. This adaptability enables warehouses to swiftly adapt to changing demand patterns, optimize resource allocation, and mitigate risks, thereby enhancing operational resilience in an ever-changing environment.

Planning Tools

Furthermore, AI-driven optimization extends beyond the confines of individual warehouses, facilitating seamless coordination and synchronization across entire supply chain networks. Through the integration of AI-powered forecasting and demand planning tools, warehouses can anticipate customer needs with unprecedented accuracy, enabling upstream suppliers to adjust production schedules accordingly. This level of supply chain visibility and coordination not only minimizes inventory holding costs but also reduces stockouts and improves customer satisfaction.

AI-Powered Navigation Systems

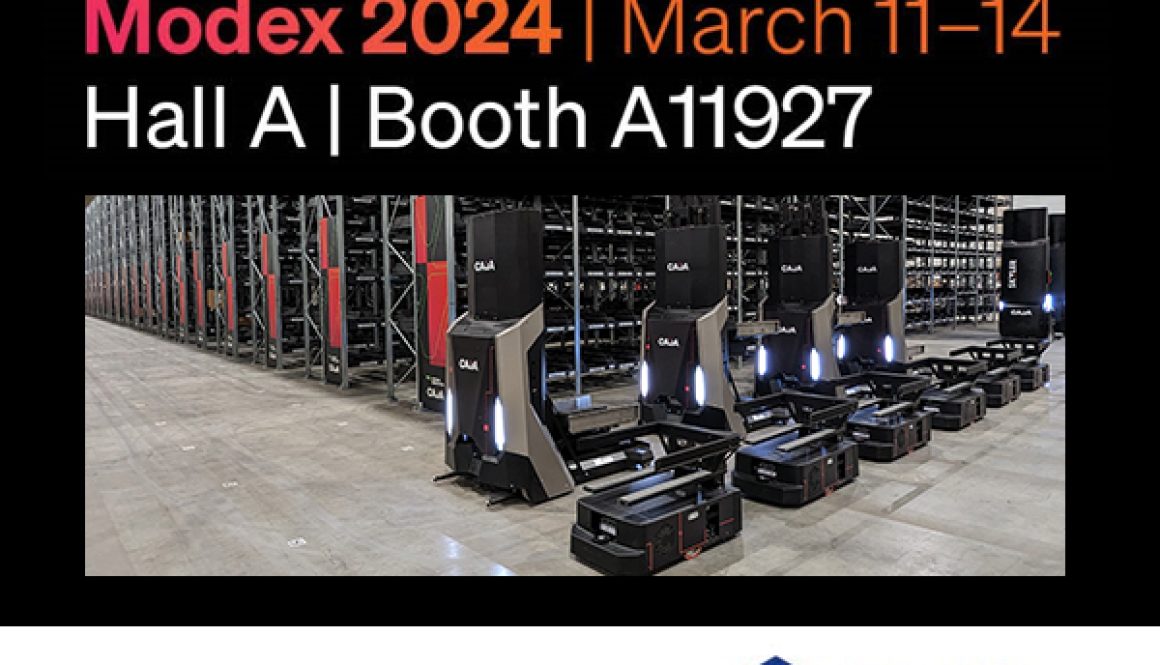

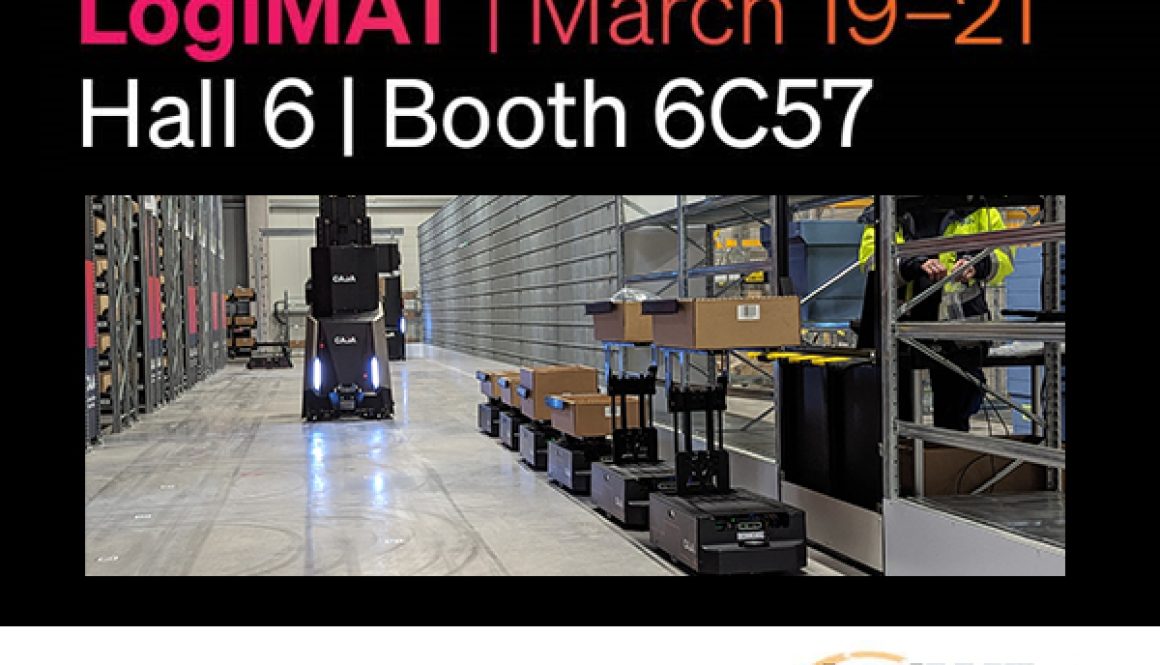

Another compelling aspect of AI-driven warehouse optimization is its ability to unlock new frontiers in robotics and automation. Autonomous mobile robots (AMRs) equipped with AI-powered navigation systems can navigate warehouse floors with unparalleled precision, optimizing pick paths and maximizing throughput. Collaborative robots, or cobots, work alongside human workers, leveraging AI algorithms to perform repetitive tasks with speed and precision while ensuring safety and ergonomic compliance. By seamlessly integrating AI and robotics, warehouses can achieve new levels of efficiency, scalability, and flexibility in their operations.

Warehouse Management

Moreover, AI-driven predictive maintenance has emerged as a game-changer in warehouse management. By analyzing equipment sensor data and historical maintenance records, AI algorithms can anticipate potential equipment failures before they occur, enabling proactive maintenance interventions to prevent costly downtime. This predictive approach not only extends the lifespan of warehouse assets but also minimizes unplanned disruptions, ensuring uninterrupted operations and optimal resource utilization.

Future Prediction

In addition to these features, AI-powered warehouse optimization offers the ability to predict future orders and identify items that are unlikely to be needed. By analyzing historical sales data, market trends, and customer behavior, AI algorithms can forecast upcoming orders with remarkable accuracy, allowing warehouses to proactively adjust inventory levels and allocate resources accordingly. Furthermore, AI-driven predictive analytics can identify slow-moving or obsolete items, enabling warehouses to optimize storage space and minimize inventory holding costs.

Sustainability

Beyond operational efficiency, AI-driven warehouse optimization holds profound implications for sustainability and environmental stewardship. By optimizing inventory placement and routing, warehouses can minimize transportation distances and carbon emissions, contributing to a greener and more sustainable supply chain ecosystem. Additionally, AI-powered energy management systems can optimize lighting, heating, and cooling systems based on real-time occupancy and environmental conditions, reducing energy consumption and lowering carbon footprints.

Conclusion

In conclusion, the integration of AI into automated warehouse systems represents a transformative leap forward in the realm of logistics and supply chain management. By harnessing the power of AI-driven optimization, warehouses can achieve unprecedented levels of efficiency, flexibility, and sustainability while navigating the complexities of modern-day supply chains. As we embrace this technological revolution, the possibilities are limitless, ushering in a new era of innovation and excellence in warehouse operations.